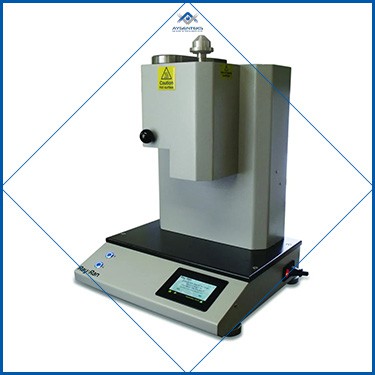

The MFR200 melt flow indexer offers a more automated procedure to the MFR100 vastly improving results accuracy for “method A” testing requirements.

The test procedure is very simple to conduct. Molten Polymer is extruded through a closely controlled orifice (die) from the apparatus using pre-set conditions of temperature and pressure produced by a dead weight system. The extruded polymer is cut off automatically and is then weighed. Using the time interval to extrude the polymer its flow rate over 10 minutes can easily be determined. Test results are given as the Melt Flow Index (MFI). A density at melt temperature test can also be conducted.

The MFR series of Melt Flow Indexers are supplied as standard with a replaceable hardened steel cylinder liner which can be simply swapped if a replacement is needed or for Hastelloy (optional) if testing corrosive materials is a requirement. A Tungsten Carbide test die and hardened steel piston along with 2.16 kg test load and tooling ancillaries compliment the apparatus to get you testing straight out the box.

The apparatus features a rotary “Auto Cut Device” feature for consistent cutting accuracy of the extrudate eliminating the need for manual cutting.

For simplicity of use the apparatus is fitted with an intuitive 4″ colour touch screen panel and microprocessor interface so test parameters can easily be set. Features include, temperature set point value (SV), actual temperature value (AV), number of cuts, cut time, auto MFI calculation and “ECO” mode. Simply weigh the cut samples and enter the weights as a mean or individual cut and let the microprocessor calculate the MFI value.

The integrated temperature controller and PT100 Platinum Resistance Thermocouple accurately control the barrel temperature to 0.01°C. Dual zone heating gives accurate temperature deviation along the length of the barrel to international test standards.

All documentation is supplied including a product user manual and a fully traceable calibration certificate.

Optional weights up to and including 21.6kg can be supplied to cover all testing parameters to International Test standards and for the heavier weights the optional pneumatic weight loader can fitted to the apparatus for ease in loading the piston. The weight loader can also be used to hold a cleaning tool so cleaning can be done more simply. The improved die release feature makes removing the test die a simple task.

Please be aware that this machine has no computer connectivity or file capture software functionality.

Although the MFR value is not a fundamental property of the polymer, it does however, give an indication of the flow characteristics of the polymer and it has become one of the most widely used references for the quality control of polymers.

The machine is available in either 220-240v 50hz or 110v 60hz

MFI:

Temperature SV input

Temperature AV display

Number of cuts

Time between cuts

Mean or individual weight entry

Auto MFI calculation

Density @ melt temperature test and auto calculation.

Optional Ancillaries

Pneumatic Weight Loader 150psi (11 bar) max

Full range of test weights available from 1kg to 21.6kg

Hastelloy cylinder, liner and die for corrosive materials.